Views: 0 Author: Site Editor Publish Time: 2021-09-16 Origin: Site

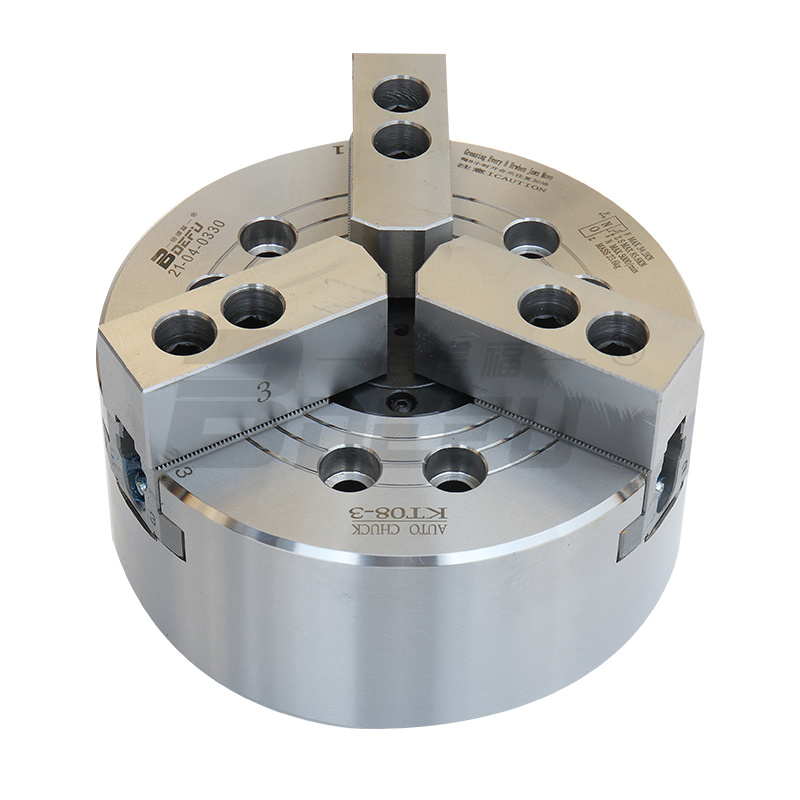

The precision three-jaw self-centering chuck is an industrial product with automatic centering function.

1. Use a voltaic wrench to rotate the bevel gear. The bevel gear drives the flat rectangular thread, and then drives the three claws to move centripetally. Because the pitch of the flat rectangular thread is equal, the movement distance of the three claws is equal, which has the effect of automatic centering.

2. Installation of three-jaw self-centering chuck:

(1) Loosen the three positioning screws and take out the three small bevel gears;

(2) Loosen the three fastening screws and take out the dust cover and the large bevel gear with flat threads;

(3) When installing the chuck, insert the square tenon of the chuck wrench into the square hole of the small bevel gear and rotate it to drive the plane thread of the large bevel gear to rotate. When the screw thread of the flat thread is turned to be close to the housing groove, install the No. 1 catch into the housing groove. The remaining two cards are loaded in order of No. 2 and No. 3. The installation method is the same as before.

Advantages of three-jaw self-centering chuck:

(1) The three jaws of the three-jaw chuck move synchronously and can automatically center. Generally, no correction is required after the workpiece is installed. However, if the workpiece is long, the rotation center of the part far away from the chuck may not necessarily coincide with the rotation center of the lathe spindle, and the workpiece needs to be corrected. If the three-jaw chuck has been used for a long time and the accuracy decreases, and the processing part of the workpiece requires higher accuracy, it also needs to be corrected.

(3) The three-jaw chuck is convenient for clamping workpieces and saves time, but the clamping force is small, so it is suitable for clamping small and medium-sized parts with regular shapes, such as cylindrical, regular triangle, regular hexagonal workpieces, etc.

Three-jaw automatic centering chuck specifications are: 150mm, 200mm, 250mm.