Views: 0 Author: Site Editor Publish Time: 2021-10-01 Origin: Site

1) Reduce labor intensity and enhance corporate image

The use of pneumatic chucks can not only improve production efficiency, but also greatly reduce the workload of workers, making your company a model of caring for workers. It can also add new highlights to corporate personnel recruitment and improve product market competitiveness. It can also improve the quality of equipment and enhance the overall image of the company. It is the first choice for equipment improvement for large-volume mechanical processing companies.

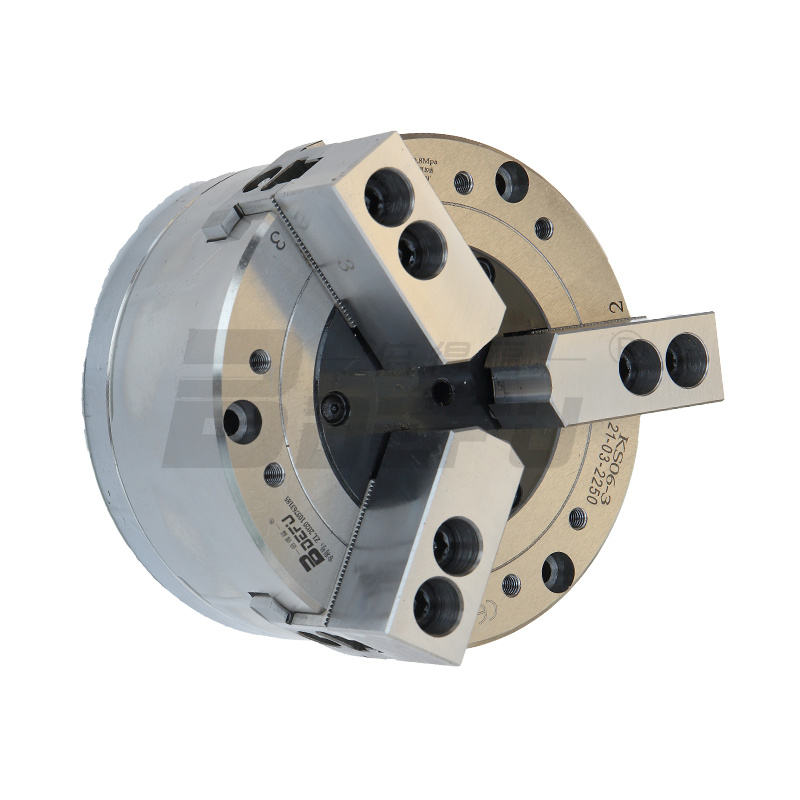

2) Simple structure and easy installation

The complete set of pneumatic chuck is configured as chuck, pneumatic gyrator and electronic control part. No tie rods are required during installation, which changes the shortcomings of traditional pneumatic and hydraulic chucks such as complex structure and troublesome installation (generally, it takes 2 working days for professionals to install). By reading the installation instructions and schematic diagram, users can complete the entire installation process in about 1 hour. This can not only save users high installation fees and production costs, but also improve the operating efficiency of machine tools for users.

3) No need to use consumables and invest in one step

Compared with hydraulic chucks, pneumatic chucks have simple structures, low usage costs and failure rates, and are environmentally friendly and pollution-free. They mainly use air as the power source. Only one 1 cubic air pump can operate 8-10 pneumatic chucks at the same time. There is no air leakage when the pneumatic gyrator is partially clamped and loosened, which can save air sources and reduce the use and maintenance costs (such as hydraulic oil) incurred by using hydraulic chucks. It allows you to invest in one step. It is currently the most economical and practical chuck in China.

4) Large clamping force and wide clamping range

The independent innovation and unique design of the pneumatic chuck has improved the shortcomings of traditional pneumatic chucks with small clamping force and unstable force. For example, the ¢200 pneumatic chuck can normally clamp 45 steel for 5mm cutting on one side without slipping, and the clamping force is stable, reliable and adjustable. Customers can choose comb tooth soft claws, hard claws, customized special-shaped claws, etc., and can adjust the comb position according to the size of the workpiece to process various parts.

5) High clamping accuracy and long service life

The pneumatic chuck adopts a fully enclosed structure, carefully selected parts, and all mating surfaces are dust-proof. In addition, the unique material selection and heat treatment process exceed the service life of the manual chuck (the service life of a manual chuck is generally half a year to one year). If the pneumatic chuck is properly maintained and used, the service life can reach more than 3 years, and it can maintain the factory accuracy for a long time, so that your investment can maintain its value for a long time. The repeated clamping accuracy is generally 0.01-0.03mm.

6) Strong safety and reliability:

The pneumatic chuck generates force through the conversion of air pressure and wedge angle. In addition to strong clamping force, the pneumatic chuck also has a strong self-locking function. It has passed the national statutory agency inspection and test. The 3Mpa water pressure test shows that the chuck structure does not deform and all parts are not damaged. When the air source is disconnected, the workpiece can still be firmly clamped for cutting, which completely solves the safety and reliability problems for customers.