Views: 0 Author: Site Editor Publish Time: 2021-09-15 Origin: Site

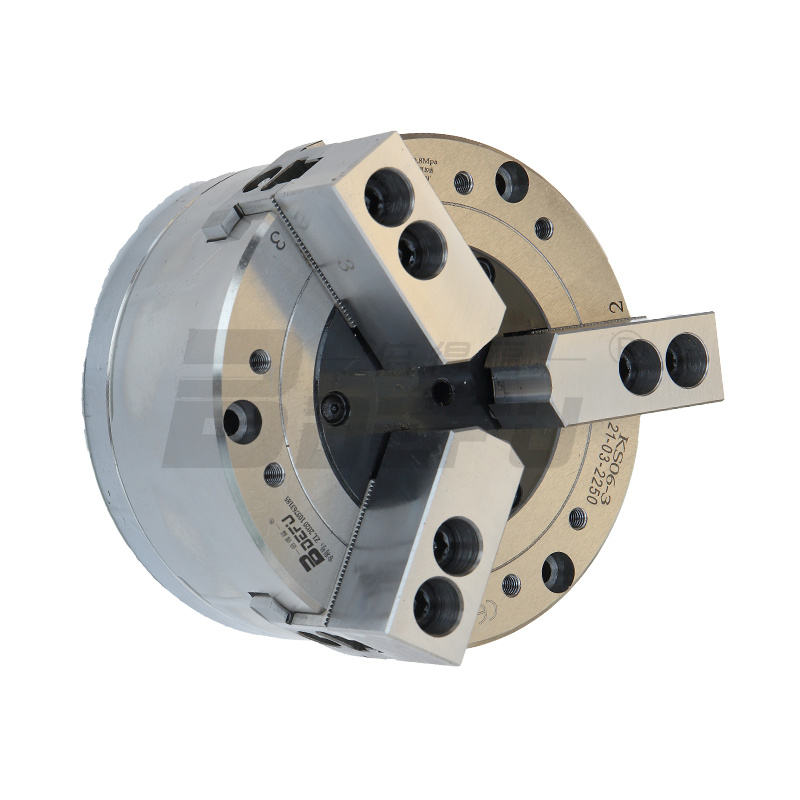

Composition and principle of three-grip chuck 'Chuck' is a mechanical device used to clamp workpieces on machine tools.

From the number of jaws of the chuck, it can be divided into: two-jaw chuck, three-jaw chuck, four-jaw chuck, six-jaw chuck and special chuck. In terms of power, it can be divided into: manual chuck, pneumatic chuck, hydraulic chuck, electric chuck, dynamic chuck and mechanical chuck.

From the structure, it can also be divided into: hollow type and medium solid type. The three-claw chuck uses a voltaic wrench to rotate the bevel gear. The bevel gear drives the plane rectangular thread, and then drives the three claws to move centripetally. Because the pitch of the rectangular thread on the chuck surface is equal, the three claws move at the same distance, which has the effect of automatic centering. The three-jaw chuck is composed of a large bevel gear, three small bevel gears, and three claws. Three small bevel gears mesh with the large bevel gear. The back of the large bevel gear has a plane thread structure, and three claws are equally installed on the plane thread. When the small bevel gear is turned with a wrench, the large bevel gear rotates, and the plane thread on the back of it causes the three claws to approach or withdraw from the center at the same time.

Basic structure and working principle: The three-jaw self-centering chuck uses three screws to fasten the chuck to the machine tool flange through the screw holes on the end face of the plate body. Insert the wrench into the square hole of any gear. When the wrench is turned, the pinion drives the coil wire to rotate. Through the rotation of the thread on the end face of the coil wire, it drives the three claws to advance or separate at the same time.