Views: 0 Author: Site Editor Publish Time: 2021-09-13 Origin: Site

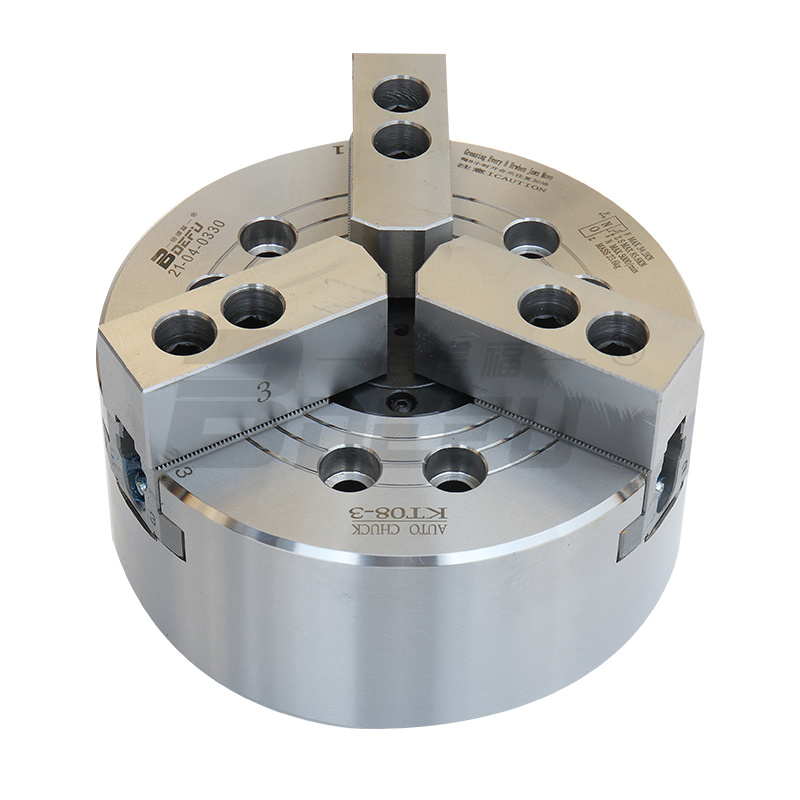

When the three-claw chuck is used for a long time, the coaxiality will decrease and the bell mouth phenomenon will occur, which directly affects the processing accuracy and clamping reliability. Practice has proved that using the following method to correct it is simple, practical and effective, so you might as well give it a try. Taking the positive jaw chuck as an example, first use an external clamp to clamp a round bar of appropriate diameter, start the machine tool, and turn the outer circular part of the jaw. Then use an inner support to clamp a ring-shaped piece, start the machine tool, and turn the inner circular part and end face of the claw. Obviously, this can significantly improve the coaxiality between the machined inner circle of the claw and the machine tool spindle, eliminate the bell mouth phenomenon, obtain higher accuracy, and achieve the purpose of correction.

The following points should be noted during specific applications:

1. The outer circle of the round rod and the inner circle of the ring must be processed in advance and have a certain degree of accuracy. Moreover, the inner diameter of the annular body should not be too small, otherwise the claw surface will have a deep concave arc, which will easily damage the surface of the workpiece when clamping large-diameter workpieces, so attention must be paid.

2. Since there is an inevitable gap between the claws and the chute of the chuck body, and the force direction of the claws during correction is exactly opposite to the force direction during actual operation, the corrected chuck will have a bell mouth phenomenon when used. Therefore, during correction, the inner circle of the claw should be pre-processed into a reverse bell mouth with a certain taper (big inside and small outside). The adjusted taper value can be determined through experiments, which is the key to success or failure.

3. Due to the high hardness of the claws and the intermittent cutting, the cutting depth and tool feed should be small during correction, and the cutting speed should not be too high. The best tool material is carbide. If a small power head can be installed on the carriage and the grinding wheel can be used for correction, the effect will be better.

4. The purpose of requiring the outer circle of the claw to be cut for the first time is to establish a good benchmark to improve the correction accuracy. It is best not to skip this step.

5. This method can also be used to correct errors caused by improper installation of the new three claws or other reasons to improve processing accuracy.

6. The same principle can also be used to correct the anti-claw.