Views: 0 Author: Site Editor Publish Time: 2021-08-22 Origin: Site

Using cutting oil with anti-rust effect can prevent rust inside the chuck, because rust in the chuck will reduce the clamping force and prevent the workpiece from being clamped

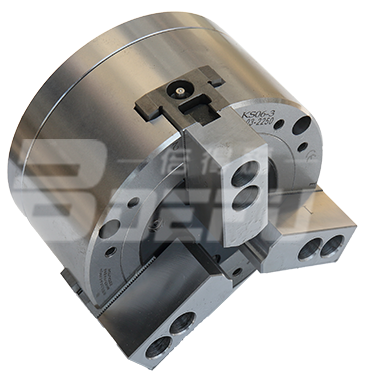

'Bedford' brand three-jaw chuck is independently produced under its own brand. It has been specialized in manufacturing chucks and jaws for more than 10 years. It has cooperated with many domestic and foreign chuck manufacturers. In line with the principle that quality is the productivity of the enterprise, strict inspection is carried out one by one before leaving the factory. Customers can buy with confidence.

The power is output through a 0.75KW three-phase asynchronous motor fixed at the end of the machine tool. The power is transmitted to the transmission shaft through the coupling. The transmission shaft directly drives the reduction device inside the chuck, thereby driving the coil wire to rotate and causing the claws to move centripetally or centrifugally, thereby achieving the purpose of holding the workpiece.

Our company's chuck is a mechanical device used to clamp workpieces on machine tools. A machine tool attachment that uses the radial movement of the movable jaws evenly distributed on the chuck body to clamp and position the workpiece. The chuck generally consists of three parts: the chuck body, the movable jaw and the jaw driving mechanism. The diameter of the chuck body is as small as 65 mm and as large as 1500 mm. The chuck has a through hole to allow the workpiece or bar to pass through; the back has a cylindrical or short conical structure, which is connected to the end of the machine tool spindle directly or through a flange. The chuck is usually installed on lathes, cylindrical grinders and internal cylindrical grinders. It can also be used with various indexing devices on milling machines and drilling machines.

According to the number of jaws of the chuck, it can be divided into: two-jaw chuck, three-jaw chuck, four-jaw chuck, six-jaw chuck and special chuck. In terms of power, it can be divided into: manual chuck, pneumatic chuck, hydraulic chuck, electric chuck, dynamic chuck and mechanical chuck. Structurally, it can be divided into: hollow chuck and medium solid chuck.