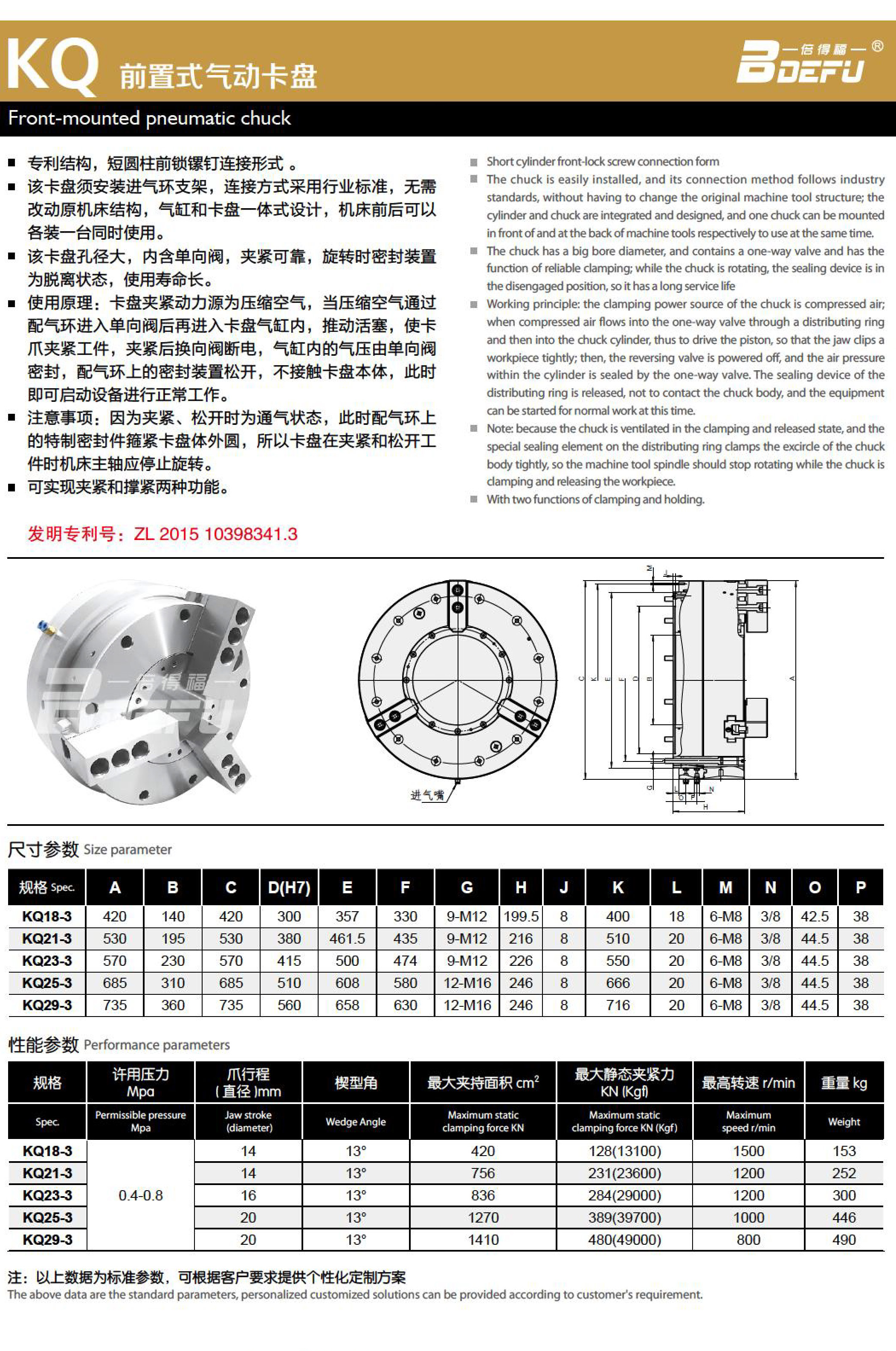

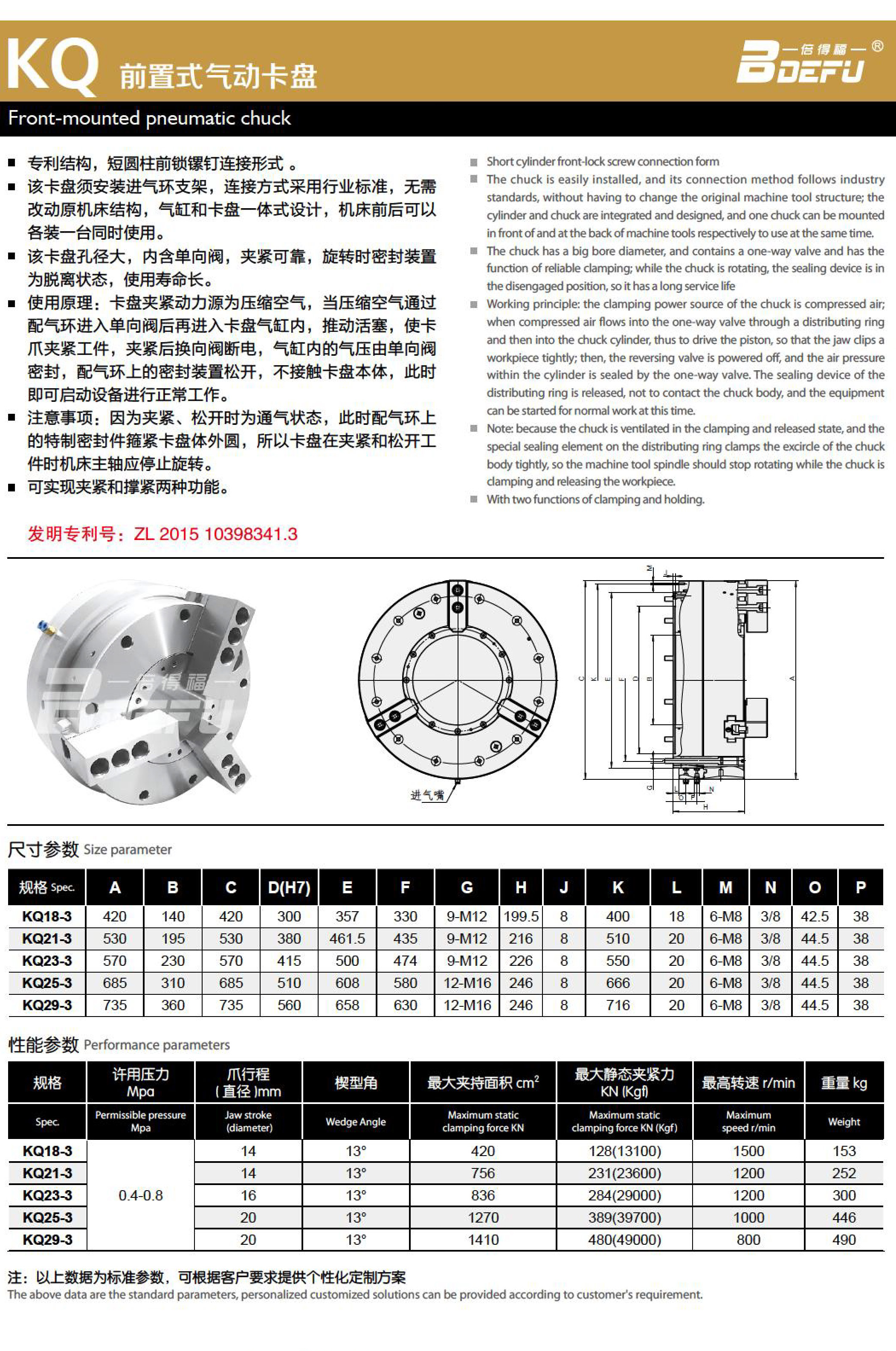

Patented structure, short cylindrical front locking screw connection form.

The chuck must be installed with an air inlet ring bracket, and the connection method adopts industry standards. There is no need to change the original machine tool structure. The cylinder and chuck are designed in an integrated manner. One can be installed at the front and rear of the machine tool and used at the same time.

The chuck has a large hole diameter and contains a one-way valve, which ensures reliable clamping. The sealing device is in a disengaged state when rotating and has a long service life.

Principle of use: The power source of the chuck clamping is compressed air. When the compressed air enters the one-way valve through the air distribution ring and then enters the chuck cylinder, it pushes the piston to make the jaws clamp the workpiece. After clamping, the reversing valve is powered off. The air pressure in the cylinder is sealed by the one-way valve. The sealing device on the air distribution ring is loosened without contacting the chuck body. At this time, the equipment can be started for normal operation.

Note: Because the machine is in a ventilated state when clamping and unclamping, and the special seal on the air distribution ring tightens the outer circumference of the chuck, the machine spindle should stop rotating when the chuck clamps and unclamps the workpiece.

It can realize both clamping and bracing functions.

| Availability: | |

|---|---|

| Quantity: | |

KQ

倍得福

KQ18-3.PDF

KQ18-3.PDF  KQ20-3.PDF

KQ20-3.PDF  KQ18-3.STEP

KQ18-3.STEP  KQ21-3.PDF

KQ21-3.PDF  KQ20-3 model diagram.STEP

KQ20-3 model diagram.STEP  KQ21-3 model diagram.STEP

KQ21-3 model diagram.STEP  KQ25-3.PDF

KQ25-3.PDF  KQ25-3 model diagram.STEP

KQ25-3 model diagram.STEP  KQ30-3.PDF

KQ30-3.PDF  KQ30-3 model diagram.STEP

KQ30-3 model diagram.STEP  KQ12-3 model diagram.STEP

KQ12-3 model diagram.STEP  KQ100-3 model(1).STEP

KQ100-3 model(1).STEP  KQ100-3 assembly(1).PDF

KQ100-3 assembly(1).PDF  KQ08-3.PDF

KQ08-3.PDF  KQ10-3 model diagram.STEP

KQ10-3 model diagram.STEP  KQ12-3.PDF

KQ12-3.PDF  KQ08-3 model diagram.STEP

KQ08-3 model diagram.STEP  KQ06-3 model diagram.STEP

KQ06-3 model diagram.STEP  KQ06-3.PDF

KQ06-3.PDF  KQ10-3.PDF

KQ10-3.PDF  KQ04-3 model diagram.STEP

KQ04-3 model diagram.STEP  KQ05-3 model diagram.STEP

KQ05-3 model diagram.STEP  KQ04-3 model diagram.PDF

KQ04-3 model diagram.PDF  KQ05-3.PDF

KQ05-3.PDF