Views: 0 Author: Site Editor Publish Time: 2021-10-11 Origin: Site

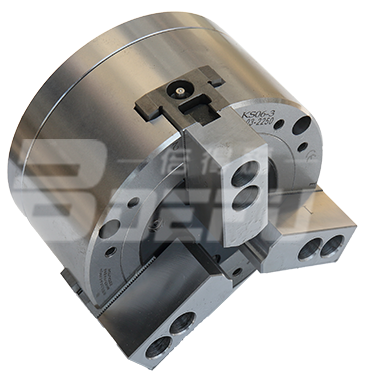

The power chuck is a functional component of the machine tool that clamps and positions the workpiece through hydraulic, pneumatic or electric means, using the radial movement of the movable jaws distributed on the chuck body. With the popularization of CNC machine tools and the increasing demand for improving production efficiency, power chucks are increasingly used, including hydraulic power chucks and supporting cylinders.

Working principle of power chuck: According to the different power sources of current power chucks, common power chucks are divided into three categories: hydraulic power chuck, pneumatic power chuck (referred to as pneumatic chuck) and electric chuck. Among them, the hydraulic power chuck combines hydraulic transmission technology and self-centering chuck technology. It takes advantage of the large power density ratio of hydraulic transmission and has the advantages of large clamping force, high speed, and compact structure. Hydraulic power discs have been widely used in CNC machine tools and have become indispensable basic functional components for medium and high-speed CNC lathes, CNC grinders and CNC turning and milling centers. The hydraulic power chuck is generally connected to the high-speed rotary cylinder through a draw tube that passes through the spindle. The high-speed rotary cylinder consists of a rotary part and a fixed part, and the two parts are connected through a distribution pair. The rotating part is connected to the machine tool spindle and can rotate with the spindle at high speed; the fixed part is connected to the machine tool bed and does not rotate with the spindle. When the oil cylinder is working, it realizes the axial movement of the piston by switching the oil inlet and outlet, and then transmits it to the chuck through the draw tube. Finally, the axial movement is converted into the radial movement of the claw through the transmission mechanism inside the chuck, so as to clamp and loosen the workpiece. Flow distribution, pressure maintenance and self-locking are the three key technologies in the design and manufacture of high-speed rotary cylinders. Flow distribution technology solves the problem of severe heating of distribution pairs. Deformation caused by heat will cause adhesion, wear and even locking of the cylinder; self-locking technology solves the hydraulic self-locking problem of the rotary cylinder, which is of great significance to improve the stiffness of the chuck system and reduce the loss of clamping force; pressure-maintaining technology solves the problem of reliability and stability of the push-pull force of the high-speed rotary cylinder, which directly affects the safety of the workpiece processing process.

The working principle of the pneumatic chuck is similar to that of the hydraulic power chuck. The rotary cylinder replaces the rotary cylinder.

Pneumatic chuck uses compressed air to drive the piston movement in the cylinder to achieve the chuck clamping action. Pneumatic chucks are often used on ordinary lathes, simple CNC lathes and lathes where it is inconvenient to install a rotary cylinder. A cylinder is fixed with a flange on the left end of the lathe spindle 12, and the compressed air passes through the air pipe, the air distribution switch, and the air channel into the right side of the cylinder. The piston moves to the left, driving the long arm of the tie rod and crankshaft rod to move, and the short arm rod causes the claw to clamp the workpiece. At this time, the air on the left side of the cylinder is discharged along the air passage, gas distribution switch, and exhaust port. If you turn the handle of the gas distribution switch to connect the port to the pipe and the exhaust port to the airway, the compressed air will flow in the opposite direction and the claw will automatically release. The cylinder of the pneumatic device rotates together with the main shaft, and the air channel connector 7 is fixed. In order to reduce the friction between the coupling and the cylinder block, a rolling bearing is installed in the middle, and padding is used to prevent air leakage.

An electric chuck is a power chuck driven by an electric motor. The clamping and loosening of the chuck is achieved by controlling the forward and reverse rotation of the motor through the switch on the electrical control box. Adjusting the voltage regulating knob on the electrical control box can adjust the drive voltage and change the motor output torque, thereby adjusting the clamping force of the chuck. The characteristics are: high speed, high precision and long life. The disadvantage is that it requires a motor control system and drive motor, which is expensive.