Views: 0 Author: Site Editor Publish Time: 2021-06-21 Origin: Site

During the operation of the pressure plate clamp, we first clearly understand the scope and content of the work we have to do. Today I will summarize the fixtures that we often use in use.

1. Summary of universal pressure plate clamps

1. Chuck, Chuck can be said to be familiar to us as a robot rather than a familiar fixture. Chuck is a hundred years old. This is a classic fixture.

2. Vise, wort. If the platen is unable to hold the workpiece, consider using a vise or grain clamp.

3. Magnetic platform. Magnetic platforms are easy to use, but relatively expensive.

4. Spindle and tool holder. The crystallization of human wisdom and technology.

5. Spring sleeve/bushing, through which and the tool holder, tools of different specifications can be clamped.

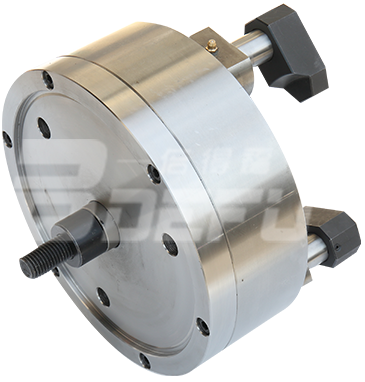

6. Cylinder clamp is the essence of automatic fixture.

7. Dividing head. It used to be beautiful. It gradually declined with the advent of indexing spindles.

2. Classification of pressure plate clamps

1. Classification of machine tool fixtures

(1) Classification by professional level

1) Universal fixture

A universal fixture is a standardized fixture that can process different workpieces within a certain range.

For example, three-jaw chucks, four-jaw single-action chucks on lathes, flat clamps, dividing heads, turntables on milling machines, etc. These clamps are generally produced by professional manufacturers and are often provided to users as machine tool accessories.

It is characterized by wide adaptability and low production efficiency. Mainly suitable for single piece and small batch production.

2) Special fixture

Special fixtures refer to fixtures specially designed for a certain process of the workpiece. Only suitable for fixed products and mass production.

3) Universal adjustable clamps and combination clamps

Its characteristic is that some parts of the fixture can be replaced, and some devices can be adjusted to adapt to the processing of different parts. Fixtures used for group processing of similar parts are called group fixtures. Compared with group clamps, general adjustable clamps are not very clear about the processing objects and have a wider application range.

4) Combined fixture

The combination fixture is a fixture assembled from a set of pre-manufactured standard parts according to the processing requirements of the parts. It has the characteristics of strong flexibility, short manufacturing cycle and reusable parts. Especially suitable for new product trial production and single-piece small batch production.

5) Matching fixture

A follower clamp is a clamp used on automatic lines. The fixture not only plays the role of clamping the workpiece, but also is integrated with the workpiece and moves from one station to the next along the automatic line to implement different processes.

(2) Classification by machine tools used

Due to the different working characteristics and structural forms of various machine tools, different requirements are put forward for the structure of the fixture.

According to the different machine tools used, pressure plate fixtures can be divided into: lathe fixtures, milling fixtures, drilling fixtures, boring fixtures, grinder fixtures, gear fixtures and other machine tool fixtures.