Views: 0 Author: Site Editor Publish Time: 2021-06-17 Origin: Site

The field of CNC machine tool processing is no stranger to fixtures. CNC machine tool processing requires the assistance and stability of fixtures to ensure the accuracy of processed parts, reduce labor intensity, and improve production efficiency. There are many types of machine tools, and different machine tools are used to process different workpieces. Next, I will introduce to you the specific functions of the pressure plate clamp, as well as commonly used clamps.

1. What is the function of the pressure plate clamp?

1. Can stably ensure the machining accuracy of the workpiece: When clamping the workpiece with a pressure plate clamp, the clamp ensures the positional accuracy of the workpiece relative to the tool and machine tool. It is not affected by the technical level of workers, so that the processing accuracy of a batch of workpieces tends to be consistent.

2. Reduce auxiliary working hours and improve productivity: the workpiece can be quickly positioned and clamped without alignment. The auxiliary working time is significantly reduced; the clamp is used to clamp the workpiece, which improves the stiffness of the workpiece and increases the cutting volume. Multi-piece multi-station pressure plate clamps are used to clamp the workpiece, and an effective clamping mechanism is adopted. These factors are conducive to improving labor productivity.

3. It can expand the scope of use of machine tools and achieve multi-functionality of machine tools: The use of special fixtures can change the use of original machine tools, expand the scope of use of machine tools, and achieve multi-functionality of machine tools. For example, after installing a boring fixture on a lathe or radial drilling machine, the hole system of the box can be bored; the lathe can be transformed into a broaching machine through a special fixture, giving full play to the role of ordinary machine tools.

4. Reduce workers’ labor intensity: It is convenient and quick to clamp the workpiece with a pressure plate clamp. The use of pneumatic, hydraulic and other clamping devices can reduce the labor intensity of workers.

2. Introduction to common pressure plate clamp types

1. The universal combination fixture is suitable for small batch production or development of milling of small and medium-sized workpieces on CNC milling machines.

2. Special milling fixtures are specially designed and manufactured for one or more similar workpieces. Usually used for mass production or development.

3. The multi-station fixture can clamp multiple workpieces at the same time, reducing the number of tool changes and facilitating single-sided processing. Simultaneous loading and unloading of workpieces reduces preparation time. Suitable for medium-volume production.

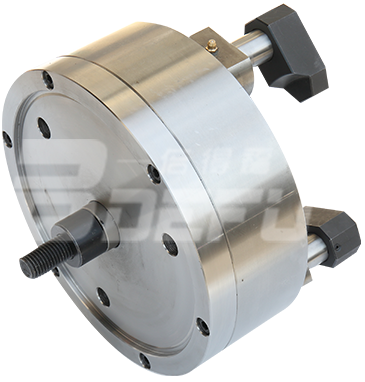

4. Pneumatic or hydraulic clamps are suitable for mass production, while other clamps are particularly labor-intensive. It can reduce labor intensity and improve productivity, but the structure of this fixture is relatively complex. Costs tend to be higher and manufacturing cycles longer.

5. Vacuum clamps are suitable for positioning workpieces with flat surfaces or large sealing areas. Some CNC mills (such as wall panel mills) have their own universal vacuum platform. When installing the workpiece, the regularly shaped rectangular blank can be adjusted. Special rubber strips can be used directly, and hollow or solid circular sections with certain size requirements can be embedded in the sealing groove of the pressure plate clamp. Then put it into the blank space and start the vacuum pump to clamp the blank.