Views: 0 Author: Site Editor Publish Time: 2022-05-05 Origin: Site

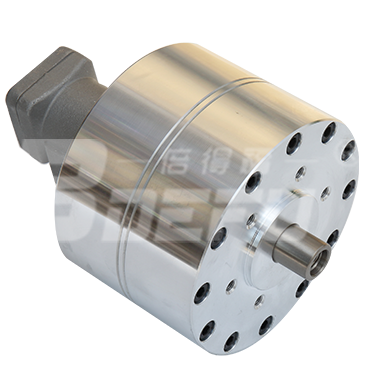

The hollow double-piston cylinder manufacturer believes that when the piston rod is used in a hydraulic gas-liquid booster cylinder, its processing quality must be guaranteed. Generally, the processing requirements of piston rods are very high, requiring surface roughness of Ra 0.4 ~ 0.8 um, and strict coaxiality and wear resistance. Therefore, in order to meet the requirements of normal use, when making the piston rod, it is important to ensure that its length is appropriate. Generally speaking, the length value is controlled between 0.7 ~ 1.0 times the outer diameter (outer edge diameter) of the piston rod. This is mainly to enhance its guiding role, but also to expand the force-bearing area, reduce the degree of wear (a basic type of parts failure), and maximize the service life of the hydraulic gas-liquid booster cylinder.

Hollow double-piston cylinder manufacturers believe that piston rods are mainly used in hydraulic and pneumatic, engineering machinery, automobile manufacturing piston rods, guide posts of plastic machinery, rollers of packaging machinery and printing machinery, shafts of textile machinery and conveying machinery, and linear optical axes of linear motion. Since the piston rod of the hydraulic gas-liquid booster cylinder will bear a large load under multiple tensions, it must be designed according to its actual use requirements. However, under multi-pressure conditions, good longitudinal stability is required.

Hollow double-piston cylinder manufacturers believe that the processing technology of the piston rod includes:

(1) During normal use, the piston rod must withstand alternating loads and the surface must rub back and forth, so the piston rod is required to have both high hardness and wear resistance.

(2) The piston rod is generally made of 38CrMoALA material, partially quenched and tempered, and the surface is nitrided. Its core hardness is 28-32HRC, surface hardness is 62-65HRC, and it has certain toughness.

(3) The piston rod has a relatively simple structure, but the aspect ratio is relatively correct. It is a slender shaft type part, but its rigidity is not very good. Therefore, in order to ensure the processing accuracy, when processing the piston rod, rough turning and finishing turning must be performed separately to prevent the workpiece from deforming during the processing. Also note that when machining threads at both ends, a center frame should be used.

(4) When selecting the positioning datum, all processing procedures should adopt the positioning method of two center holes and be unified and standardized. This is done to ensure the tolerance of part coaxiality and the accuracy of the relative position of each part.

(5) The manufacturer of the hollow double-piston cylinder believes that when grinding the cylindrical surface, elastic deformation is likely to occur, thus affecting the accuracy of the piston rod. Therefore, the center hole should be repaired, kept clean, properly tightened with the top, and well lubricated. In addition, the width of the grinding wheel should be narrow to reduce radial grinding forces.

(6) When grinding taper, the test piece should be ground first. After the test piece passes the grinding inspection, taper grinding can begin.

(7) The manufacturer of the hollow double-piston cylinder believes that in order to ensure the stability of the piston rod processing accuracy, manual alignment is not allowed during the entire processing process; during nitriding, the threaded part of the piston rod should be equipped with a protective device for protection.