Views: 0 Author: Site Editor Publish Time: 2021-11-04 Origin: Site

Research on CNC lathe hydraulic chuck clamping control system

Mainly researching the hydraulic chuck clamping control system of CNC lathes, established a model of the relationship between the clamping force and rotation speed of the power chuck, analyzed the clamping force compensation based on the change of oil supply pressure with speed, designed the oil circuit of the power chuck clamping control system, and verified through experiments that the chuck control system using hydraulic pressure compensation has better high-speed performance.

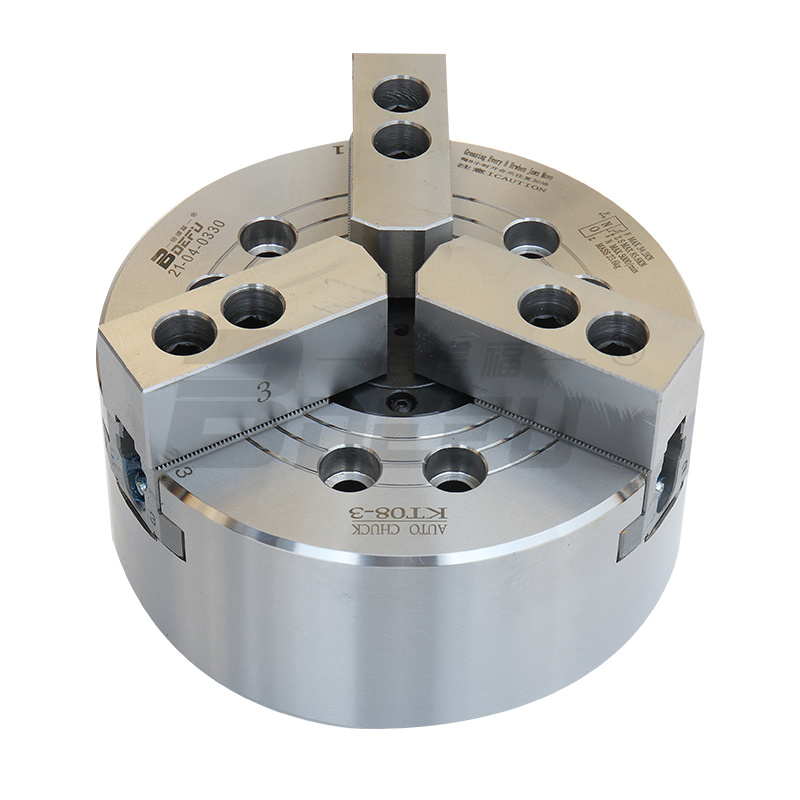

Modern processing technology is developing towards high efficiency and high precision, which places high speed and high precision requirements on CNC machine tools and their fixtures. The power chuck is the most commonly used workpiece fixture in CNC lathes. It is the bridge connecting the lathe spindle and the workpiece. The movement and accuracy of the lathe spindle are transmitted to the workpiece through the chuck. The hydraulic power chuck, which perfectly combines hydraulic transmission technology and self-centering chuck technology, has become an indispensable basic functional component of current CNC lathes.

At present, the maximum speed of the electric spindle of domestic CNC lathes can reach tens of thousands of revolutions per minute, but the maximum speed that the hydraulic chuck can adapt to has not yet reached this requirement. The low speed of the hydraulic power chuck restricts the development of CNC machine tools towards high speeds. In order to improve the backward status of hydraulic chucks, we should learn from foreign advanced technical experience to conduct research and innovation on the localization of high-speed hydraulic chucks, narrow the technological gap with developed countries such as Germany and Japan, and meet the needs of the domestic market.