Views: 0 Author: Site Editor Publish Time: 2022-02-04 Origin: Site

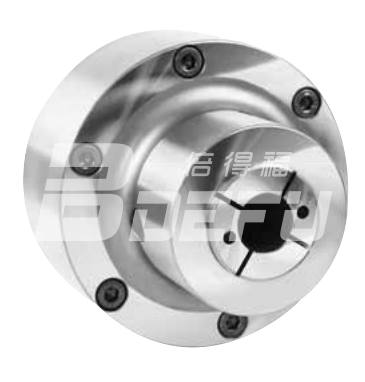

In order to obtain better accuracy and stability in machining, pneumatic chuck has become an important component. There are two main types of chucks on the market : domestic chucks and imported chucks.

Chuck jaws can be divided into double-jaw chucks, three-jaw chucks, four-jaw chucks, six-jaw chucks and special chucks. In terms of power, it can be divided into : manual chuck, pneumatic chuck, hydraulic chuck, electric chuck and mechanical chuck. Structurally, it can be divided into : hollow chuck and solid chuck.

In order to ensure that the pneumatic chuck can still maintain good accuracy after long-term use, lubrication becomes particularly important. Improper or inappropriate lubrication can lead to abnormal function at low pressure, weakened clamping force, poor clamping accuracy, abnormal wear and binding, so pneumatic chucks must be properly lubricated.

First, apply molybdenum disulfide grease ( black ) at least once a day , and drive the grease into the nozzle until the grease overflows the surface of the jaw or the inner hole of the chuck ( at the inner hole protective sleeve and connecting nut ) . But if it rotates at high speed or uses a large amount of water-based cutting oil for processing, more lubrication is required, which should be decided according to different situations. Second, at the end of the operation, be sure to clean the chuck body and sliding surfaces with an air gun or similar tool. Then, the chuck must be disassembled and cleaned at least 6every month to keep the sliding surface of the jaw clean and lubricated to extend the service life of the chuck. In addition, use cutting oil with anti-rust effect to prevent rust inside the chuck, prevent the chuck from rusting, reduce the clamping force, and make the workpiece unable to be clamped.

Paired with a suitable pneumatic chuck, the CNC machine tool will play a more powerful role. Manufacturers must make choices based on the actual conditions of their products so that they can function better.