Views: 0 Author: Site Editor Publish Time: 2021-06-03 Origin: Site

1. Take out the connecting sleeve, screw on the screw, and connect it to the tail of the spindle. Use a dial indicator to correct the outer circle and end face runout of the connecting sleeve to control it within 0.05millimeters, and tighten the screws.

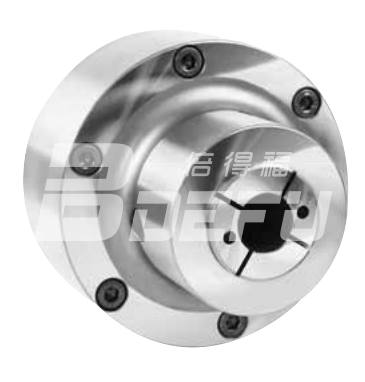

2. Take out the chuck, wipe it clean with a rag, and use a caliper to measure whether the lathe flange size is consistent with the chuck connection size. If not, complete the flange to the chuck size.

3. Take out the spiral air duct, set the decorative hoop, and install the air duct on the ventilation joint of the chuck. Then use a vise to clamp the clamp and do not damage the air pipe during installation.

4. Wrap the trachea in sections with capsules to ensure smoothness, and then mark the tail of the trachea with 1a number and 2a number. Then use a thin wire to pass the air pipe through the lathe spindle, so that the air pipe passes through the spindle smoothly, and the support chuck moves backward synchronously and is gently buckled on the flange.

5. Take out the screws, fix the chuck on the flange, and measure the cylinder runout ≦0.05。

6. Tighten the air pipe, cut off the excess air pipe at the tail, and leave it about 50-100MM long outside the main shaft . And it can naturally bounce back into the main shaft, and then try to blow 1the trumpet and 2air pipe to observe whether the movement of the chuck is smooth.

7. Use the hoop to connect 1the No. and No. air pipes to 2the No. and 1No. air nozzles 2on the pneumatic rotor respectively , and then clamp the hoop.

8. Use the thread at the connecting sleeve to connect the rotating air pressure gyrator, and then try to blow 1the horn and 2the horn air hole. Observe whether the chuck moves smoothly to prevent the air tube of the pneumatic rotator from twisting.

9. Fix the ' anti-rotation screw ' on the lower part of the pneumatic gyrator to prevent it from rotating with the spindle.

10. First fix the circuit board and switch on the lathe, close to the air pressure gyrator, then connect the air pipes one by one and introduce 220volt or 24V power supply.

11. Fill the oil tank on the oil-water separator with oil, ventilate and adjust the pressure and oil output, energize the machine tool, and operate the switch to make the chuck move smoothly.