Views: 0 Author: Site Editor Publish Time: 2021-07-29 Origin: Site

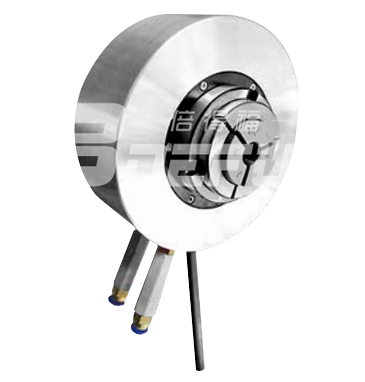

A collet is a locking device that clamps workpieces and is commonly used on drilling and milling machines and machining centers. The following is the installation method of the collet chuck shared by the editor.

First, the installation steps of the collet chuck

1. Check whether the thread of the connecting nut can be locked into the connecting pipe.

2. Tighten the connecting nut onto the sleeve.

3. Reduce the oil pressure to the lowest level and drive the hydraulic cylinder to stop the piston at the front end. Rotate the chuck to lock the connecting nut into the threads of the connecting pipe. When locking, the taper hole of the chuck must be concentric with the taper of the spindle, and the alignment hole of the chuck must be aligned with the alignment button on the nose of the spindle.

4. Operate the hydraulic cylinder to move the piston backward, combine the taper of the chuck with the spindle, and confirm that the centering button is installed in the chuck.

5, lock the screw to fix the chuck and the spindle, gradually increase the oil pressure, and repeatedly drive the chuck to the maximum allowable thrust.

Then there are the steps to install the collet chuck.

1. Remove the limit cover,

2. Install the collet on the stop cap, and then install the collet into the sleeve.

3. Reinstall the stop cover to the body, tighten the screws, and check whether the clamping stroke of the chuck is correct.

The above is the content collected by the editor of Bidefu Machinery Technology (Changzhou) Co., Ltd. If necessary, please contact us. The company specializes in the production of floating chucks, indexing chucks, vertical hydraulic chucks, vertical pneumatic chucks, laser cutting chucks, hydraulic center frames, pneumatic gyrators, back-pull hydraulic chucks, front-mounted pneumatic chucks, clamping jaws, collets, power chucks, platen clamps, shaft processing chucks, synchronous clamps, oil cylinders, and air cylinders. The company is a technology-based joint-stock company integrating R&D, production, sales and service. The company has strong technical strength, advanced production equipment, perfect quality system, strong production capacity, unique product structure, safety and reliability, and stable performance. All products are well received by users with reasonable prices, reliable quality, and perfect services.