Views: 0 Author: Site Editor Publish Time: 2022-08-24 Origin: Site

With the development of society, we have also seen that many products will slowly be replaced. China is now in the best historical period in the past two hundred years. Even hydraulic center stands are widely used. Let me give you a detailed introduction below.

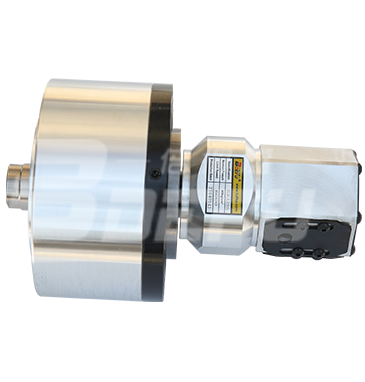

The development prospects of the hydraulic center frame industry are very good. Because it brings many benefits to the enterprise when used, it is favored by customers. Nowadays, there are still many people who do not understand some basic information about the hydraulic center frame. Therefore, as a manufacturer, it is necessary for us to briefly explain how to avoid too big deviations in the hydraulic center frame? There are often some problems when using this product. This is what most people are concerned about. In fact, it is an auxiliary equipment that radially supports rotating workpieces during production and processing. When processing, it plays a very important role and. For example, it moves radially without any relativity to the workpiece. The use of hydraulic steady rest to cut workpieces can avoid the increase of shaft machining deviation. In addition, what everyone needs to know here is that when it is cutting the workpiece, the way to stabilize the shaft is usually to use one side of the shaft to clamp it with the headstock chuck, or to use the headstock to tighten it. At this time, the other end of the shaft is supported by the top of the tailstock. Therefore, when the CNC blade is close to the middle of the shaft, the workpiece will be deformed by its own gravity and the radial cutting force of the CNC blade.

When we use the hydraulic center stand, everyone must understand these basic information. Otherwise, the shaft will bend to varying degrees, causing deviations in production and processing, which will cause the finished shaft to become a drum shape, that is, the middle is large and the two sides are smaller. What you also need to know when operating the hydraulic center frame is that its longitudinal cross-section uniformity and roundness cannot be guaranteed. Applying a hydraulic center frame to the middle part of the workpiece can increase the bending stiffness of the shaft. If done well, you can ensure that the workpiece will not exhibit drum-shaped non-straightness and 'knife yield' during the production process. Of course, on the other hand, this approach can also prevent the occurrence of system vibration, thus avoiding the increase in shaft processing deviations. There is actually a lot of relevant information about the hydraulic center stand. We also have online customer service staff on our official website. You can consult them at any time. The prices of the products here are very reasonable and the quality is guaranteed. If your industry needs it, you can take a look. I believe it will satisfy customers.

The content of the above article is some basic information introduced by the editor on how to avoid excessive deviation of the hydraulic center frame. Anyone who didn’t know it before can come and read it. Okay, that’s all for today’s knowledge points. I hope it can be helpful to relevant people.