Views: 0 Author: Site Editor Publish Time: 2021-08-01 Origin: Site

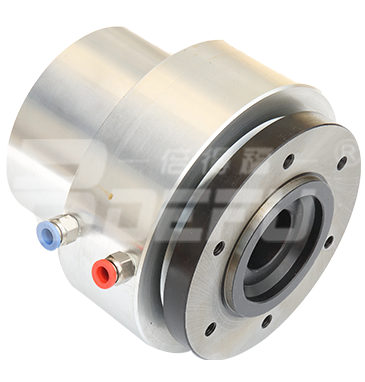

Inspecting the hollow double-piston cylinder is mainly to detect its degree of wear, that is, the roundness and cylindricity of the cylinder.

1. Measurement of cylinder bore of cylinder block

①Measurement part of hollow double-piston cylinder bore

According to the wear pattern of the cylinder, when measuring the cylinder diameter, measurements should be made at the three axial sections and directions of the cylinder. The upper section is in the upper part of the cylinder, equivalent to the position of the piston ring when the top dead center of the piston stroke is about 15mm ; it is far away from the top of the cylinder; the second section is in the middle of the cylinder, about 35mm from the top of the cylinder; the third section is in the lower part of the cylinder, close to the lower edge, about 70mm from the top of the cylinder。

②Adjust the measuring cylinder gauge and measure the length of the connecting rod

According to the diameter of the cylinder to be measured, select the appropriate measuring connecting rod and fixing nut, and screw into the lower end of the measuring rod. Adjust the length of the connecting rod so that the total length of the connecting rod and the movable measuring rod adapts to the diameter of the cylinder being measured, even though the measurement range can include the larger and smaller wear diameters of the cylinder.

③Measure the diameter of the hollow double-piston cylinder with small wear. The less worn cylinder bore is in the lower part of the cylinder, so place the measuring rod of the cylinder scale closer to the lower edge of the cylinder bore.

④Measure the diameter of the larger worn cylinder.

⑤Measure roundness and cylindricity errors. After measuring the larger worn cylinder diameter, measure the smaller cylinder diameter of the same cross section. For convenience, holes perpendicular to the larger wear diameter are generally considered to be smaller wear holes in the plane.

2. Calculation

The roundness and cylindricity errors of the cylinder can be calculated by using the values measured in the above steps.

3. Processing of hollow double-piston cylinder bore measurement results

Based on the measured diameter, roundness and cylindricity error values of the larger worn cylinder, compare them with the specified limit values to determine whether to repair the cylinder.