Views: 0 Author: Site Editor Publish Time: 2021-08-13 Origin: Site

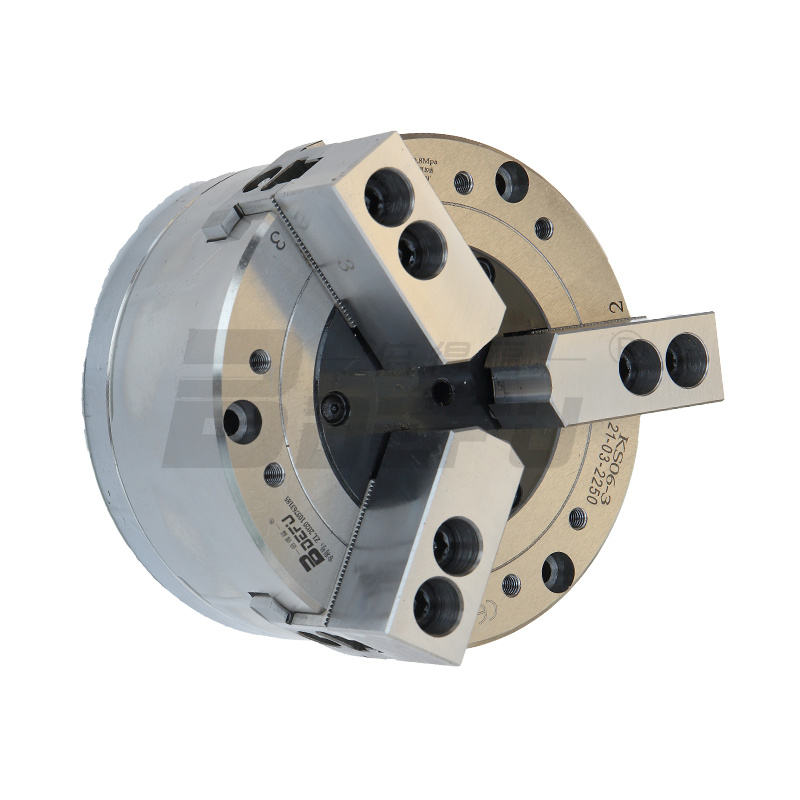

1. The manufacturing errors of the positioning parts, guide parts and tool parts on the three-jaw chuck and the amount of wear during use will change the correct positional relationship between the machine tool, the tool and the workpiece, and can cause processing deviations.

2. The size of these machining deviations can also be determined based on the calculation of manufacturing tolerances of key components of the fixture. It is also possible to measure the actual deflection of a current set of fixtures or a set of fixtures that have been used and worn. According to the measurement results, the centering error of the three-jaw chuck can usually reach 0.1~0.15mm.

3. From the structural analysis of the three-jaw self-centering chuck, basically every part of it is a clearance fit. There are certain gaps between each part. For example, the I-shaped groove of the claw and the three-claw chuck housing slide back and forth, creating a certain gap; the flat thread is sleeved on the mandrel of the housing and needs to be rotated, so there is a gap; the three-claw chuck is locked on the flange and also has radial movement. These errors together form a cumulative deviation, which is concentratedly reflected in the radial circular runout of three pieces. As the wear increases, the gaps at each position also increase significantly, which is why the centering error becomes larger.